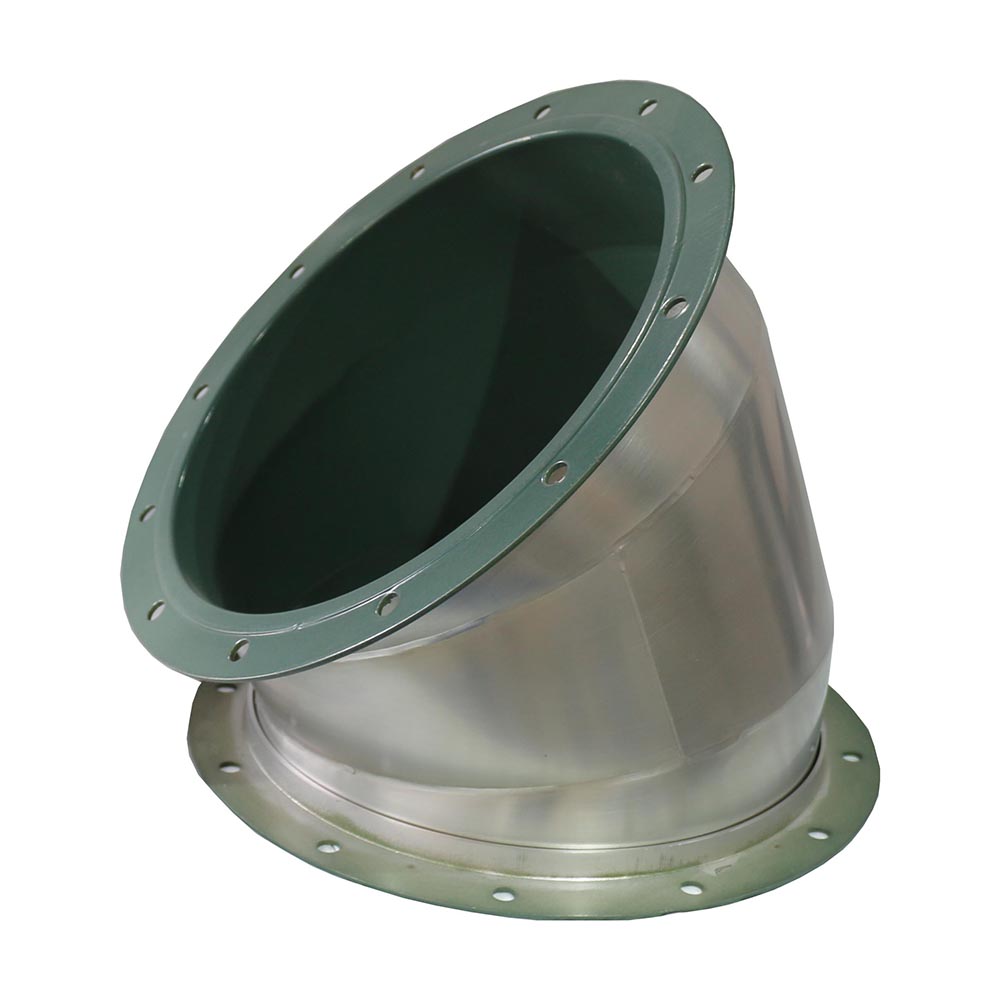

SUS304/ Rufin Teflon 45° gwiwar hannu (3 Gore)

| Labari A'a. | Diamita (mm) | Digiri | Radius (mm) | wuta (PC.) | Kauri (mm) |

| E45-0250 | 250 |

|

|

| 0.8 (ko buƙatar abokin ciniki) |

| E45-0300 | 300 |

|

|

| 0.8 (ko buƙatar abokin ciniki) |

| E45-0350 | 350 |

|

|

| 0.8 (ko buƙatar abokin ciniki) |

| E45-0400 | 400 |

|

|

| 1.0 (ko buƙatar abokin ciniki) |

| E45-0450 | 450 |

|

|

| 1.0 (ko buƙatar abokin ciniki) |

| E45-0500 | 500 |

|

|

| 1.0 (buƙatun abokin ciniki) |

| E45-0550 | 550 |

|

|

| 1.0 (ko buƙatar abokin ciniki) |

| E45-0600 | 600 |

|

|

| 1.0 (ko buƙatar abokin ciniki) |

| E45-0650 | 650 |

|

|

| 1.0 (ko buƙatar abokin ciniki) |

| E45-0700 | 700 |

|

|

| 1.2 (ko buƙatar abokin ciniki) |

| E45-0750 | 750 |

|

|

| 1.2 (ko buƙatar abokin ciniki) |

| E45-0800 | 800 |

|

|

| 1.2 (ko buƙatar abokin ciniki) |

| E45-0850 | 850 |

| R=0) l |

| 1.2 (ko buƙatar abokin ciniki) |

| E45-0900 | 900 | 45° | or | 3pcs. | 1.2 (ko buƙatar abokin ciniki) |

| E45-0950 | 950 |

| R=1.5x01 |

| 1.2 (ko buƙatar abokin ciniki) |

| E45-1000 | 1000 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1100 | 1100 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1200 | 1200 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1300 | 1300 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1400 | 1400 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1500 | 1500 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1600 | 1600 |

|

|

| 1.5 (ko buƙatar abokin ciniki) |

| E45-1700 | 1700 |

|

|

| 2.0 (ko buƙatar abokin ciniki) |

| E45-1800 | 1800 |

|

|

| 2.0 (ko buƙatar abokin ciniki) |

| E45-1900 | 1900 |

|

|

| 2.0 (ko buƙatar abokin ciniki) |

| E45-2000 | 2000 |

|

|

| 2.0 (ko buƙatar abokin ciniki) |

| E45-2500 | 2500 |

|

|

| 2.5 (ko buƙatar abokin ciniki) |

Lura:

1. Duct diamita a kan 2000mm yana samuwa akan buƙata.

2. An gina kauri mai kauri akan SMACNA "ka'idodin ginin masana'antu zagaye0azuzuwan 1 da 5 a matsa lamba -2500Pa (-10 in.wg) .Kuma ana iya canza shi azaman buƙatar abokin ciniki.

1. Ja da bututu kayan aiki a cikin shafi dakin, fara zanen, fesa da electrostatic foda shafi inji da kuma mika SPRAY gun tube, daidaita sintering lokaci moderately bisa ga halaye na albarkatun kasa na 15 ~ 20 minutes, da sintering zafin jiki kewayon ne. 285° ~ 300°C.

2.100% jimlar ingancin dubawa (gano kauri na fim, ganowar pinhole), tare da gwajin kauri na fim don gano kauri na fim.Kaurin fim ɗin shine 260 ± 30 μm.Ana amfani da na'urar gano bakin ruwa don gano ko rufin yana da ramuka.Daidaita daidaitaccen ƙarfin ganowa zuwa 2.5KV, idan akwai alluran da ke buƙatar gyara ko sake yin aiki.Kaurin fim ɗin da sakamakon gwajin pinhole bayan ingantaccen dubawa ya kamata a rubuta shi a cikin "Form Inspection Quality Inspection Duct Coatung".

3. Bayan an kammala aikin aikin, an haɗa waje da bututu tare da lakabin takaddun shaida na FM, lambar serial QC da alamar ƙayyadaddun samfur.An rufe bakin flange da farantin PE ko PP mai faffadan katako, kuma an gyara shi da tef ɗin robo.

4.Duct diamita akan 2000mm yana samuwa akan buƙata.An gina kauri akan SMACNA.Hakanan ana iya canza shi azaman buƙatar abokin ciniki.